You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

levi

Still fresh, damnit!

It's worth sticking with that story. I starts out sounding like some Amiga-head extolling some of the virtues of an outdated hypercard-based programming language, but about half way through it suddenly turns all smoke and daggers before a twist and a satisfying if somewhat emotive ending.

ClockworkCoder

Chaotic Neutral

I've just bit the bullet and got replacement caps for my A1200. Never done anything like that before (I've soldered before, but never to upgrade/fix something) so it will be a bit daunting.

However, I do know I won't be twisting any of the capacitors off! Or using a hot air gun to remove them...

However, I do know I won't be twisting any of the capacitors off! Or using a hot air gun to remove them...

- Joined

- Jan 18, 2010

- Messages

- 11,472

I've just bit the bullet and got replacement caps for my A1200. Never done anything like that before (I've soldered before, but never to upgrade/fix something) so it will be a bit daunting.

However, I do know I won't be twisting any of the capacitors off! Or using a hot air gun to remove them...

I've done both methods. Hot air even with the smallest bit you can get on your hot air reflow tool still can get messy with other components heating up. The twisting method isn't good if the pads have signs of corrosion as the pads will lift up easily on the twisting motion, but on a clean PCB it actually work quite well to my surprise.

However I think this more cautious approach in the video below of cutting the caps may be the better way. I'd just be sure to clean everything after.

levi

Still fresh, damnit!

If your caps have leaked their electolytic goodness all over the board you'd need to give it all a good cleanup anyway.

I was rather shocked when this idea of snipping through even an old and mostly empty elecrolytic came up, but this really doesn't look too bad. I twisted the first electrolytic off my old gamegear, and I think I was lucky, but I'll give this a go on the others I think. It'd be nice to see the underside of what he snips off; I'm not sure how they're sealed on the bottom, and whether you're ripping through that this way and relying on the fact they've already vented all over your nice PCB.

I was rather shocked when this idea of snipping through even an old and mostly empty elecrolytic came up, but this really doesn't look too bad. I twisted the first electrolytic off my old gamegear, and I think I was lucky, but I'll give this a go on the others I think. It'd be nice to see the underside of what he snips off; I'm not sure how they're sealed on the bottom, and whether you're ripping through that this way and relying on the fact they've already vented all over your nice PCB.

ClockworkCoder

Chaotic Neutral

I've done both methods. Hot air even with the smallest bit you can get on your hot air reflow tool still can get messy with other components heating up. The twisting method isn't good if the pads have signs of corrosion as the pads will lift up easily on the twisting motion, but on a clean PCB it actually work quite well to my surprise.

However I think this more cautious approach in the video below of cutting the caps may be the better way. I'd just be sure to clean everything after.

Thanks for that. Regarding the hot air option I heard that the capacitors can explode if you're not careful, although I think kapton tape or even foil could protect surrounding components.

I'm intrigued by the snipping method although it does look brutal (and I'm sure I'll need good quality, sharp cutters to make it clean).

Thanks for the video link too, actually I just watched a similar video of someone else doing the same but this was clearer. I may give it a go..

- Joined

- Jan 18, 2010

- Messages

- 11,472

I didn't exactly see any dramatic explosions, but when I attempting it they were expanding on me like balloons as soon as the heat touched them.Thanks for that. Regarding the hot air option I heard that the capacitors can explode if you're not careful, although I think kapton tape or even foil could protect surrounding components.

I started taping things off once I got going which helped a bit, but another issue with hot air is consistency, I found that I was lifting up pads by mistake when I had a cold spots closer to the center of the caps. It was a fine line between applying enough heat to get the part off properly and applying too much and exploding the cap.

ClockworkCoder

Chaotic Neutral

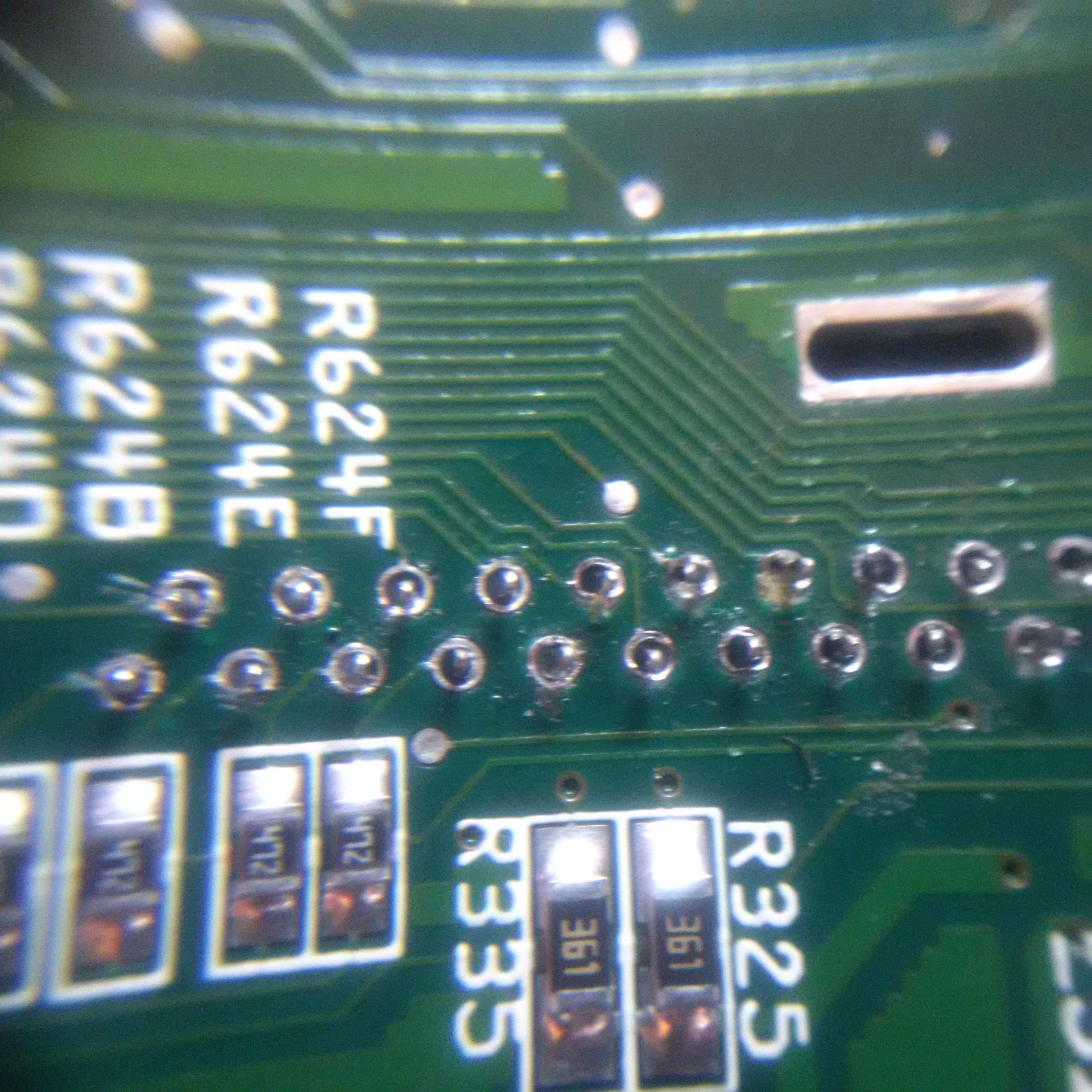

I decided to make a start on the recapping today. Haven't got far yet, as you will see...

I just got a new solder sucker (top of picture), as I thought I would have to unfortunately remove the keyboard connector (the white plastic strip at the top of the board) to gain access to the capacitor between it and the port behind. I thought with the new sucker, I should have a better chance of removing the port...

Unfortunately it wasn't so easy (my lack of knowledge / skill let me down), and I failed to remove the solder from a couple of the pins (I guess they were ground pins - actually it was mainly one, on the right, that I had problems with). I don't think I did badly, although I became more concerned that I was starting to damage the pads of the troublesome few..

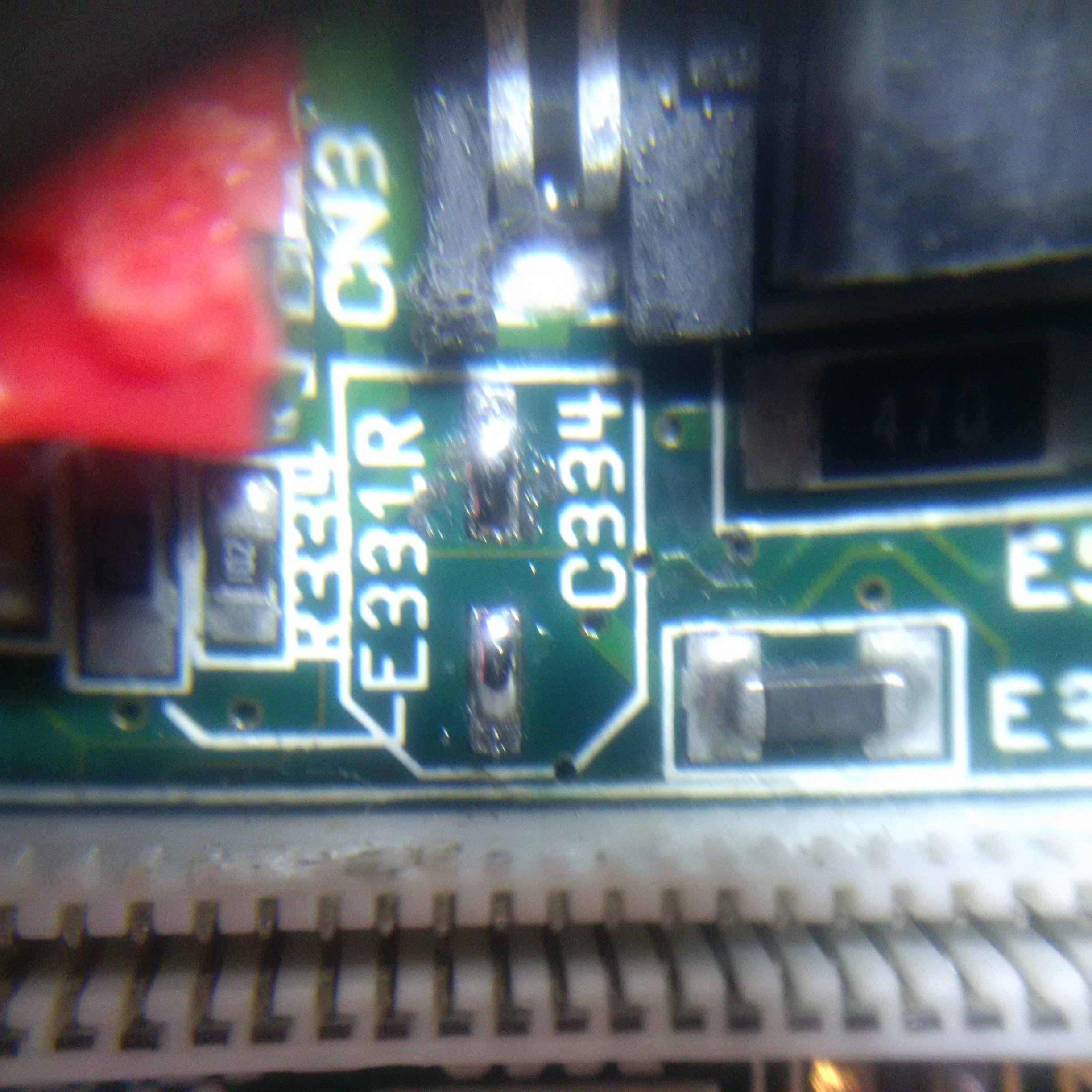

So, I looked at the keyboard connector again, and realised that part of the plastic could be removed, giving me a few more precious millimeters of access. Just enough...

shell

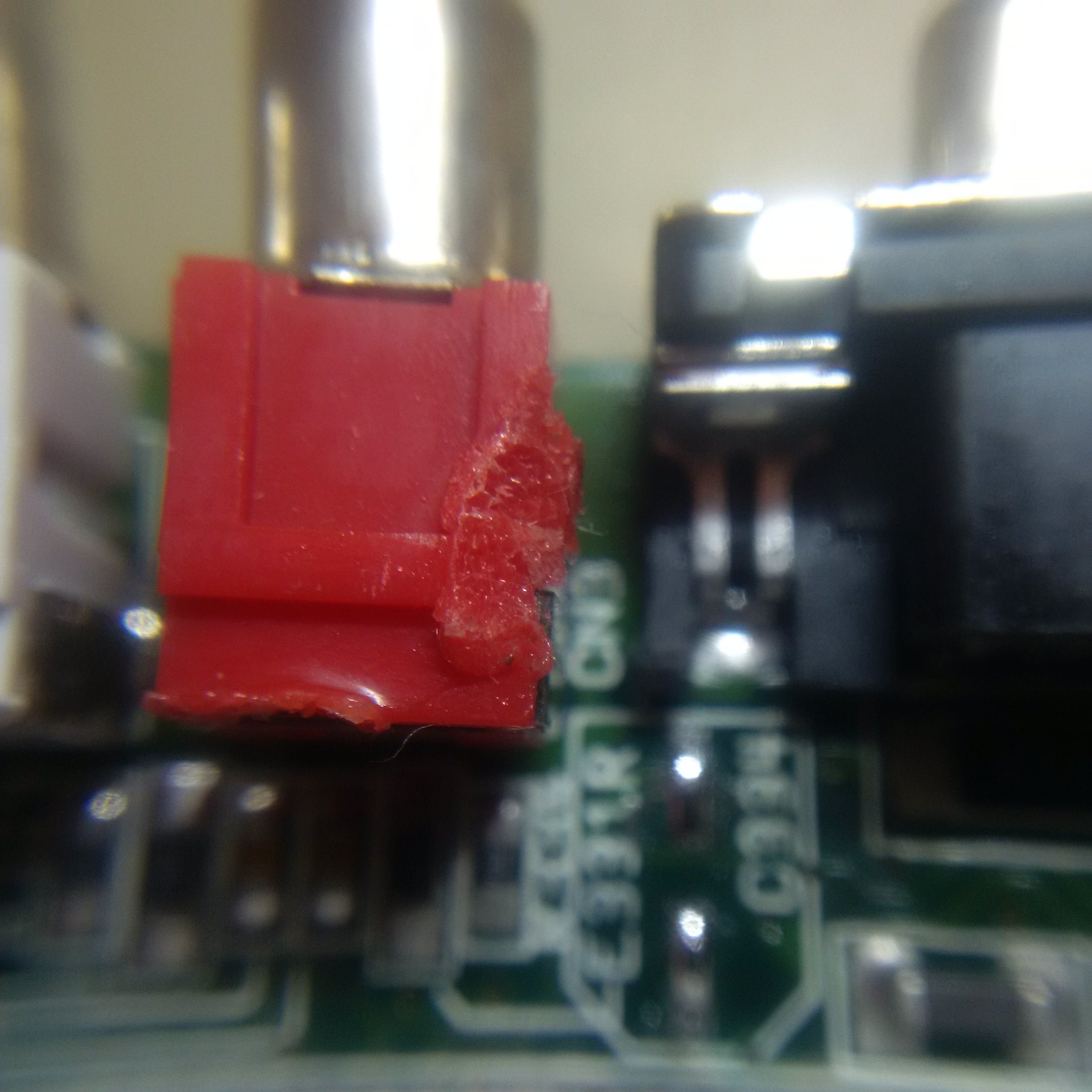

Although not quite enough, as I lost concentration, and melted one of the audio ports a little...

Slightly disappointed, but it's all part of the learning process.

I don't think it looks too bad though, so far.

However, when I started poking at the capacitor, I didn't actually think that I was going to remove it. It just started pulling away as I was poking at it. And stupidly, I forgot to note down the polarity before removing it - I believe the black stripe (negative) was pointing to the back of the board, towards the ports. Could anyone confirm this, or where might be a good place to check?

I just got a new solder sucker (top of picture), as I thought I would have to unfortunately remove the keyboard connector (the white plastic strip at the top of the board) to gain access to the capacitor between it and the port behind. I thought with the new sucker, I should have a better chance of removing the port...

Unfortunately it wasn't so easy (my lack of knowledge / skill let me down), and I failed to remove the solder from a couple of the pins (I guess they were ground pins - actually it was mainly one, on the right, that I had problems with). I don't think I did badly, although I became more concerned that I was starting to damage the pads of the troublesome few..

So, I looked at the keyboard connector again, and realised that part of the plastic could be removed, giving me a few more precious millimeters of access. Just enough...

shell

Although not quite enough, as I lost concentration, and melted one of the audio ports a little...

Slightly disappointed, but it's all part of the learning process.

I don't think it looks too bad though, so far.

However, when I started poking at the capacitor, I didn't actually think that I was going to remove it. It just started pulling away as I was poking at it. And stupidly, I forgot to note down the polarity before removing it - I believe the black stripe (negative) was pointing to the back of the board, towards the ports. Could anyone confirm this, or where might be a good place to check?

levi

Still fresh, damnit!

Yes, the negative is usually indicated by a stripe (on plastic wrapped caps) or a black painted section on a SMT alu can type. It looks to me like the side nearest that edge connector on one of your photos doesn't have any leads to it so just goes through to the ground plane, which I think would mean the signal's towards the back, although it's fair to say I don't know the circuit all that well myself.

Experts seem to use desoldering braid to clean up these joints, although back when I first tried that stuff I couldn't seem to get it to work.

Experts seem to use desoldering braid to clean up these joints, although back when I first tried that stuff I couldn't seem to get it to work.

ClockworkCoder

Chaotic Neutral

Experts seem to use desoldering braid to clean up these joints, although back when I first tried that stuff I couldn't seem to get it to work.

Yes, I tried that too. It worked fine for the capacitor connectors, especially after cleaning it, adding flux, and adding some leaded solder to the mix - was resistant to the heat before then.

Your logic on the polarity sounds sensible, although I'll look for somewhere to cross-reference, just to be doubly-sure.

Edit: Looks like it does indeed point to the back - found a photo someone posted on a different forum:

http://eab.abime.net/showthread.php?t=73089

@ClockworkCoder keep at it, looks nice! I haven't regretted recaping my A1200 but I couldn't get the job done near those audio ports and a dude from a German Amiga messageboard did it for me while debugging a cpu related freezing problem I was having.

ClockworkCoder

Chaotic Neutral

Well I got a little further today. I started by trying to "walk" the surface-mount capacitors off. The first one, mentioned above, I kind of did accidentally - feel that I literally pulled the top of the capacitor off while holding the base down with the soldering iron. It kind of worked, and cleaned up nicely.

The next couple were easier to get to, so I attempted them in a more conventional way. I did have problems getting the solder to "take" though, even after cleaning, and adding some leaded solder to the mix. The second one wasn't actually bad, and did "walk" off quite nicely, but the third was more stubborn, and I think the pad had _slightly_ started to lift on one end. Luckily it also cleaned up quite nicely, and doesn't look like it's lifted badly at least.

After that I went for the "brutal" method of cutting through them, and I can see now why it's recommended. I breezed through the remaining surface mounts, and the half-dozen I've cleaned up so far are looking perfect.

I naively thought that the through-hole caps would be relatively easy. Admittedly the first one wasn't too bad, but the second one took me ages, as I was stuck with solder blocking the hole after some persistence I managed to clear one side, and the other side now has a tiny hole, but there is still some solder remaining. Not really sure best how to tackle that one. The third one I attempted is right next to the RF modulator, and is awkward to get to, and additionally is attached to the ground plane, and as such is also persistent. I've left that one for now while I do a bit more research on how to tackle it. I'm hoping that the final capacitor will be relatively easy as it's in the centre of the board, and doesn't appear to be attached to any particularly large trace.

I'm hoping if I can more quickly deal with those remaining two, I may have a little more relaxing time of it tomorrow cleaning up and finally mounting the new caps.

Other thing I've learned - it's probably a bad idea pushing back the solder sucker over the board, as I'm now slightly concerned that I've got a few micro-blobs of solder lying around on the board. I'll have to be pretty diligent cleaning up after it's all done.

Thanks for the tips and advice so far. It's all good learning, and even if it's frustrating at times, it's good to gain some confidence attempting this, and actually see some of the theory I've seen (in stuff like EEVBlog, Ben Heck, etc) put in to practice. It's certainly very different working with an old board than one that's fresh, clean and ready for components to be installed.

The next couple were easier to get to, so I attempted them in a more conventional way. I did have problems getting the solder to "take" though, even after cleaning, and adding some leaded solder to the mix. The second one wasn't actually bad, and did "walk" off quite nicely, but the third was more stubborn, and I think the pad had _slightly_ started to lift on one end. Luckily it also cleaned up quite nicely, and doesn't look like it's lifted badly at least.

After that I went for the "brutal" method of cutting through them, and I can see now why it's recommended. I breezed through the remaining surface mounts, and the half-dozen I've cleaned up so far are looking perfect.

I naively thought that the through-hole caps would be relatively easy. Admittedly the first one wasn't too bad, but the second one took me ages, as I was stuck with solder blocking the hole after some persistence I managed to clear one side, and the other side now has a tiny hole, but there is still some solder remaining. Not really sure best how to tackle that one. The third one I attempted is right next to the RF modulator, and is awkward to get to, and additionally is attached to the ground plane, and as such is also persistent. I've left that one for now while I do a bit more research on how to tackle it. I'm hoping that the final capacitor will be relatively easy as it's in the centre of the board, and doesn't appear to be attached to any particularly large trace.

I'm hoping if I can more quickly deal with those remaining two, I may have a little more relaxing time of it tomorrow cleaning up and finally mounting the new caps.

Other thing I've learned - it's probably a bad idea pushing back the solder sucker over the board, as I'm now slightly concerned that I've got a few micro-blobs of solder lying around on the board. I'll have to be pretty diligent cleaning up after it's all done.

Thanks for the tips and advice so far. It's all good learning, and even if it's frustrating at times, it's good to gain some confidence attempting this, and actually see some of the theory I've seen (in stuff like EEVBlog, Ben Heck, etc) put in to practice. It's certainly very different working with an old board than one that's fresh, clean and ready for components to be installed.

levi

Still fresh, damnit!

How do you mean pushing back the solder sucker? You mean reloading it? All the older ones I've seen have a rod in them that tries to push out any egrarious blobs filling the spout, and ends up poking out of the end. Any solder it spits out will be well cooled, and should just fall off the board if you invert it.

Edit: on the other hand, I have seen that firing the solder sucker can sometime fire some hot flecks of solder about, which I guess it why others prefer braid.

Edit: on the other hand, I have seen that firing the solder sucker can sometime fire some hot flecks of solder about, which I guess it why others prefer braid.

ClockworkCoder

Chaotic Neutral

How do you mean pushing back the solder sucker? You mean reloading it? All the older ones I've seen have a rod in them that tries to push out any egrarious blobs filling the spout, and ends up poking out of the end. Any solder it spits out will be well cooled, and should just fall off the board if you invert it.

Edit: on the other hand, I have seen that firing the solder sucker can sometime fire some hot flecks of solder about, which I guess it why others prefer braid.

Yes, that's what I meant, and yes, it has a "self-cleaning" rod that pushes out the (cold) solder. Also I agree that it will likely just brush off, although if I miss any would likely cause a short somewhere, and I'm guessing it wouldn't be a huge stretch to imagine it lodging between a couple of connectors on one of the chips, for example.

One of the first lessons I learned as a child, with the Acorn Electron, was that pencil lead can apparently find its way through the case / keys and cause some interesting behaviour.

ClockworkCoder

Chaotic Neutral

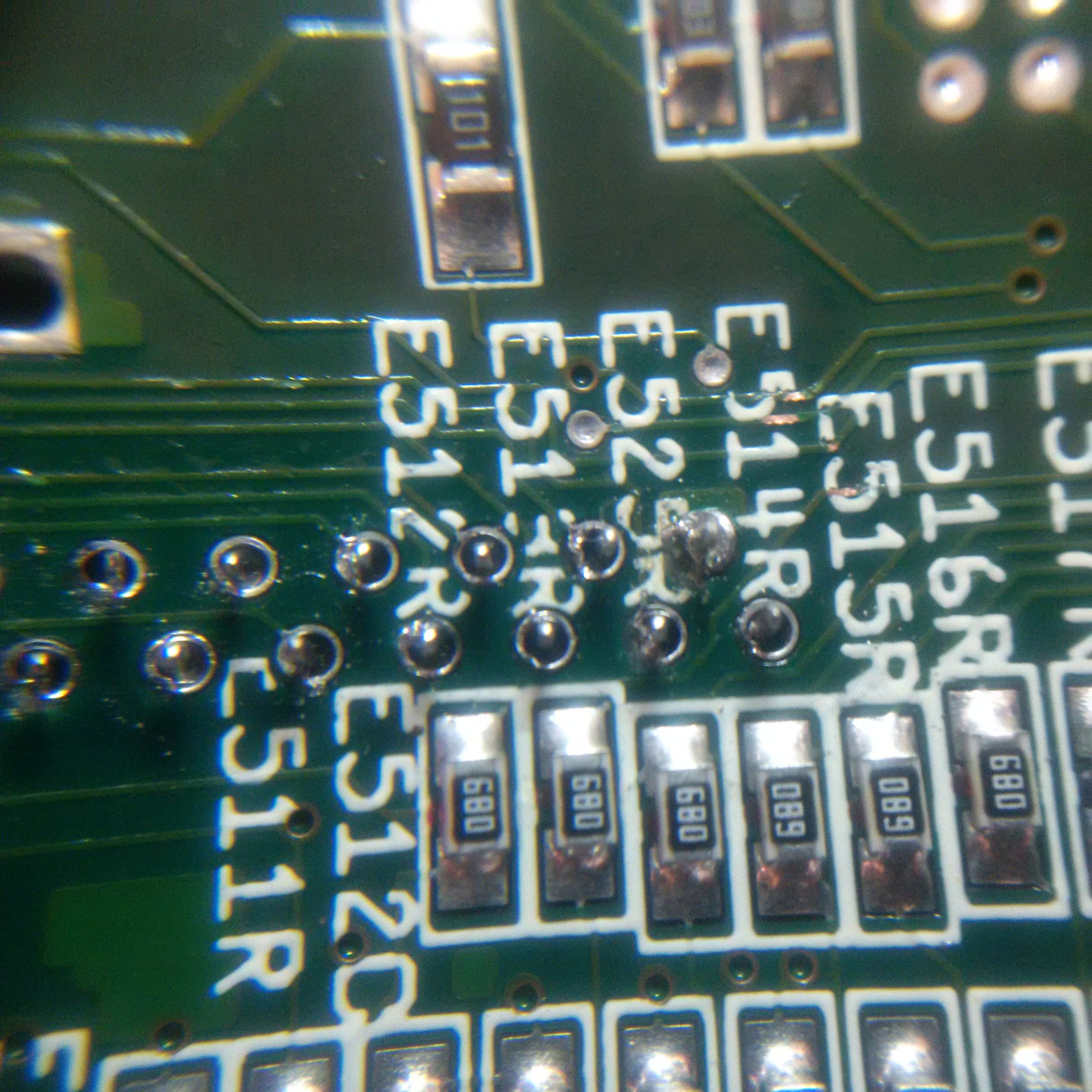

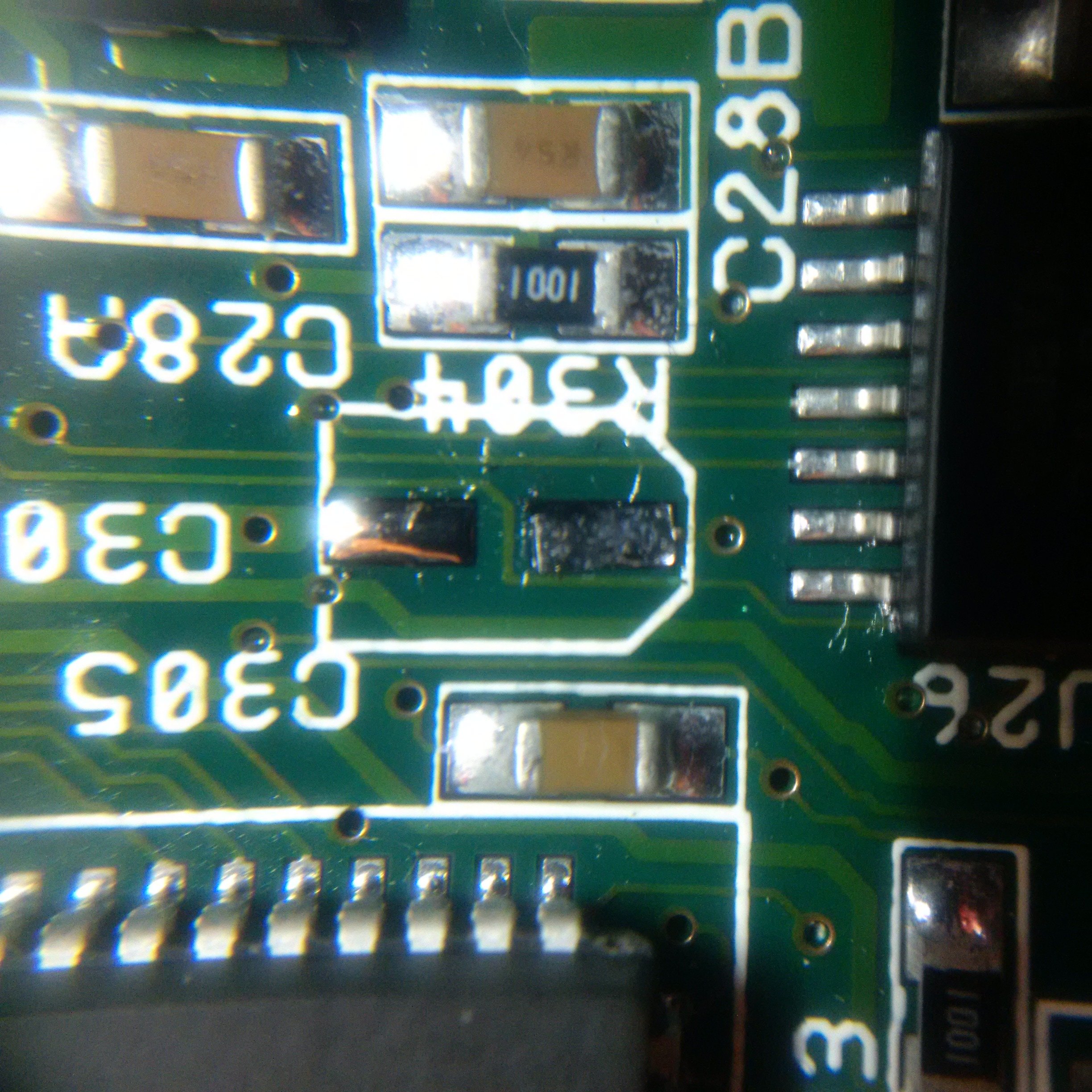

Another quick update - managed to get all of the SMD caps removed, and the pads cleaned. The one I mentioned that lifted slightly is a bit of a concern, although at least it's still connected (I checked continuity to a nearby via). Saw a couple of mentions that it could be secured with superglue, although I'm not certain if this is a good idea, or even if it's required...

You can just see in the picture that the clean pad (the one with no solder) is at a slight angle. There is a via, however, that's really close, so I'm guessing, if I needed to, I could bridge a connection there relatively easily. Not sure if anyone here has a recommendation...?

I also finally got all of the through-hole capacitors removed and the holes cleaned out. Found that the best method for doing that was to have the solder sucker the other side of the board. Was a bit tricky balancing the board and finding the exact points with the solder sucker and the soldering iron at the same time (and even trickier triggering the button on the sucker while holding its position), but it finally worked

So, the next, and hopefully final task should be the more fun chore of soldering in the new components. Might not be until next weekend though...

You can just see in the picture that the clean pad (the one with no solder) is at a slight angle. There is a via, however, that's really close, so I'm guessing, if I needed to, I could bridge a connection there relatively easily. Not sure if anyone here has a recommendation...?

I also finally got all of the through-hole capacitors removed and the holes cleaned out. Found that the best method for doing that was to have the solder sucker the other side of the board. Was a bit tricky balancing the board and finding the exact points with the solder sucker and the soldering iron at the same time (and even trickier triggering the button on the sucker while holding its position), but it finally worked

So, the next, and hopefully final task should be the more fun chore of soldering in the new components. Might not be until next weekend though...

levi

Still fresh, damnit!

It really depends how well that pad remains attached, I suspect. If you're using SMD caps then I'd have thought unless it's a *really* flakey connection, the cap should hold it firm. It may fall off if you ever need to replace *that* cap, but that's a bridge you can cross when you get to it. If you're using leaded caps (those with leads, not as in the old petrol type) then I'd be more tempted to glue down a wobbly pad, but it still depends how wobbly they are.

ClockworkCoder

Chaotic Neutral

It really depends how well that pad remains attached, I suspect. If you're using SMD caps then I'd have thought unless it's a *really* flakey connection, the cap should hold it firm. It may fall off if you ever need to replace *that* cap, but that's a bridge you can cross when you get to it. If you're using leaded caps (those with leads, not as in the old petrol type) then I'd be more tempted to glue down a wobbly pad, but it still depends how wobbly they are.

I'm thinking / hoping it will hold it in place too. At least I'll have somewhere to check if I do get any problems when it's all done.

Similar threads

- Replies

- 2

- Views

- 2K