ible

professional vim user

Any recommendations? I have some experience with modeling and CAD stuff, so it's not wholly new territory.

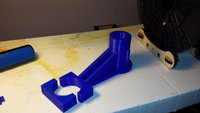

Open source, or at least Linux-capable software, is a must... Saw Lulzbot Taz 6 and thought I could support that. Sounds especially cool that I could use other materials, though I'm not sure how easy that is to do with the included parts (e.g. print head)...

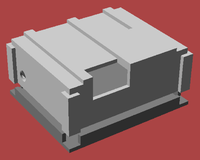

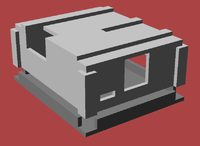

Of course, will need to save up the funds, but I figure buying one of these instead of buying a fancy new computer (when I usually just code up games for limited-resource CPUs anyways) would be a more interesting toy. Especially if I can make some fun cases for things...

Open source, or at least Linux-capable software, is a must... Saw Lulzbot Taz 6 and thought I could support that. Sounds especially cool that I could use other materials, though I'm not sure how easy that is to do with the included parts (e.g. print head)...

Of course, will need to save up the funds, but I figure buying one of these instead of buying a fancy new computer (when I usually just code up games for limited-resource CPUs anyways) would be a more interesting toy. Especially if I can make some fun cases for things...